Beans

The beans are sorted by hand to remove any foreign materials or less than perfect quality beans. Each batch of chocolate invader is made from beans from one region. The genetics, climate, and post harvest processing effect the final flavor of cocoa beans from every region, yielding unique flavors from origin to origin.

Roasting

The beans are slowly roasted and then the shells are removed.

Ingredients

We mix cocoa with evaporated cane juice and cocoa butter.

Grinding

The cocoa grinds in a granite melangeur for 4 days. When complete, its texture is extremely smooth and the flavor is nuanced and in balance. The mill uses two 40 pound granite wheels to refine the particle size of cocoa until grittiness is no longer detected on your palate.

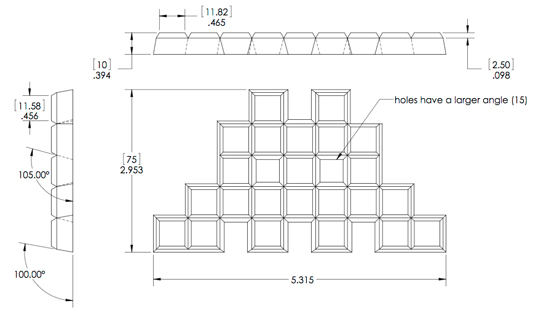

Tempering and Molding

Once finished, the chocolate is tempered and molded into invaders. Tempering is the process by which chocolate is warmed and cooled to specific temperatures in order to induce the propagation of stable cocoa butter crystals. Proper tempering will allow the chocolate to set shiny and have its characteristic snap.